Fab Lab

Fab Lab

- Home

- About Fab Lab

- Resourses And Machines

Resourses and machines

Resourses and machines

The Fab Lab has spaces on both our Segovia and IE Tower Madrid campuses. It is an unparalleled environment where our students can discover the strength of their design ideas.

Our Fab Labs have two main parts that perfectly complement one another. The digital fabrication area is replete with cutting-edge design software where they can create digital files of their projects. Then, thanks to state-of-the-art machinery like CNC routers, laser cutters, and 3D printers, students are able to produce physical objects from these files.

The other section represents a more traditional workshop, with an extensive range of woodworking tools, ceramics, and casting materials. In this way, both digital and analog techniques and processes can be seamlessly merged to create more effective models and prototypes.

As Architecture Professor and Fab Lab assistant Maxon Higbee, puts it:

“We aim to adapt to the needs of the students by offering relevant workshops and materials while also trying to anticipate their needs through providing new equipment and introducing new techniques. We do this in order to keep learning and growing as a community of makers.”

LASER CUTTERS

LASER CUTTERS

Our laser cutter machines use CO2 to produce a laser powerful enough to cut through material such as wood, paper, cardboard, acrylic, plastics without PVC, textiles, and cork, to name a few. Laser cutting is a highly practical technique that allows you to make 2D and 3D structures by joining 2D surfaces.

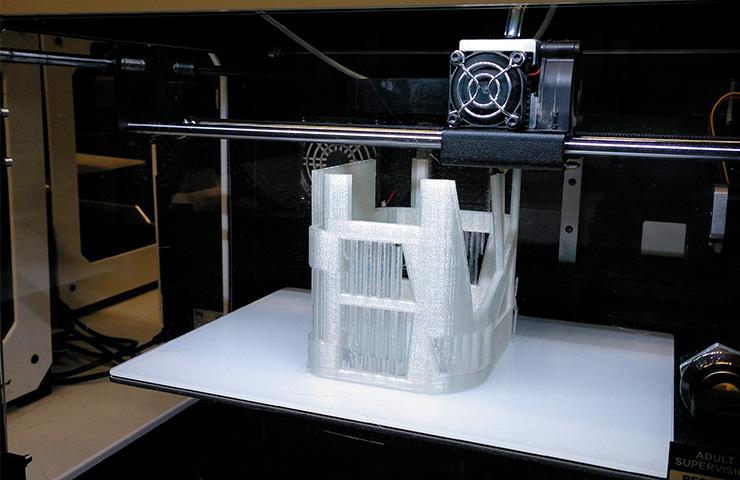

3D PRINTERS

3D PRINTERS

A 3D Printer uses what we call an additive process to construct a model. This simply means that a solid object is created by layering materials on top of each other. In the Fab Lab, our students have access to three different types of 3D Printers depending on the material they wish to use: plastic, curable resin or clay. With 3D printing, our students can design and build extremely intricate geometrical shapes that would otherwise be extremely difficult.

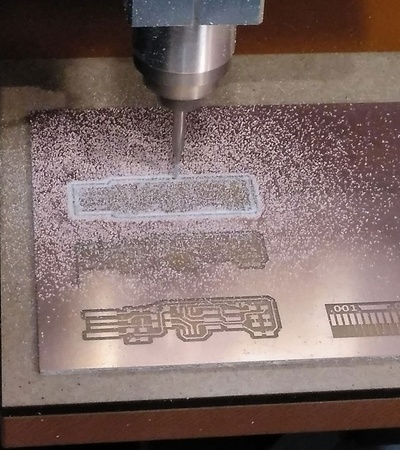

LARGE FORMAT AND PRECISION CNC MILLING MACHINES

LARGE FORMAT AND PRECISION CNC MILLING MACHINES

In contrast to 3D printers, CNC milling machines use subtracting processes to produce objects. This means that the machine removes excess, unnecessary materials from a workpiece until the desired design is reached. Using these machines, we can carve materials such as wood, extruded and expanded polystyrene, acrylic, and plastic. In this way, we can create molds for casting, prototypes in 1:1 scale, and PCBs (circuit boards).

VINYL CUTTER

A vinyl cutter machine uses a blade to cut a very thin layer of adhesive material (vinyl) that you can use then to customize almost any kind of surface.

VACUUM THERMOFORMING MACHINE

With our vacuum thermoforming machine, you can use plastic to replicate the surface of an original piece previously fashioned by laser cutting, CNC milling, 3D printing, or woodworking.

WOODSHOP

WOODSHOP

In our fully equipped woodshop, students can find all the necessary machines to develop their prototypes out of wood. These tools include table saws, circular saws, routers, band saws, sanders, drills, jigsaws, drill presses, along with the appropriate safety equipment.

EVEN MORE TOOLS...

EVEN MORE TOOLS...

In our Fab Lab, there are even more state-of-the-art machines and tools our students can use to realize their vision. For example, they will have access to a 3D scanner for real objects, which allows you to work with their digital files on a computer. There is also a potter’s wheel to make your own clay objects by hand and a kiln for hardening them.

Students can also find a heat press machine to transfer vinyl to a textile material, a welding area with tools and materials to make wire metal structures or create your own PCBs (circuit boards), a spray-painting area, and even a printing press.

LEARN MORE ABOUT OUR FAB LAB FROM OUR FABLAB MANAGERS

LEARN MORE ABOUT OUR FAB LAB FROM OUR FABLAB MANAGERS